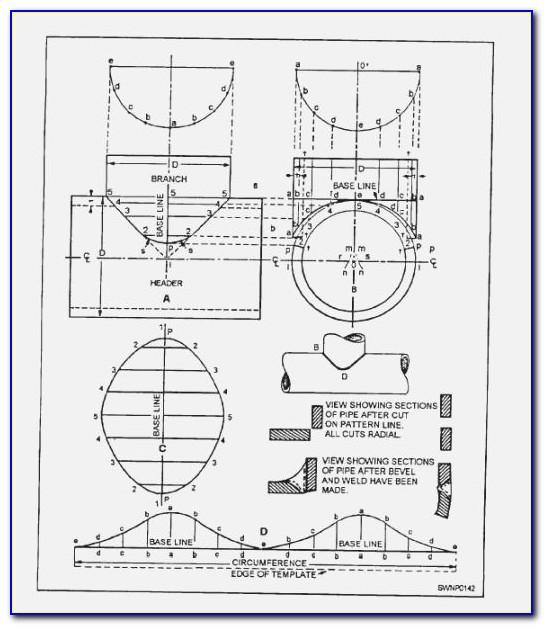

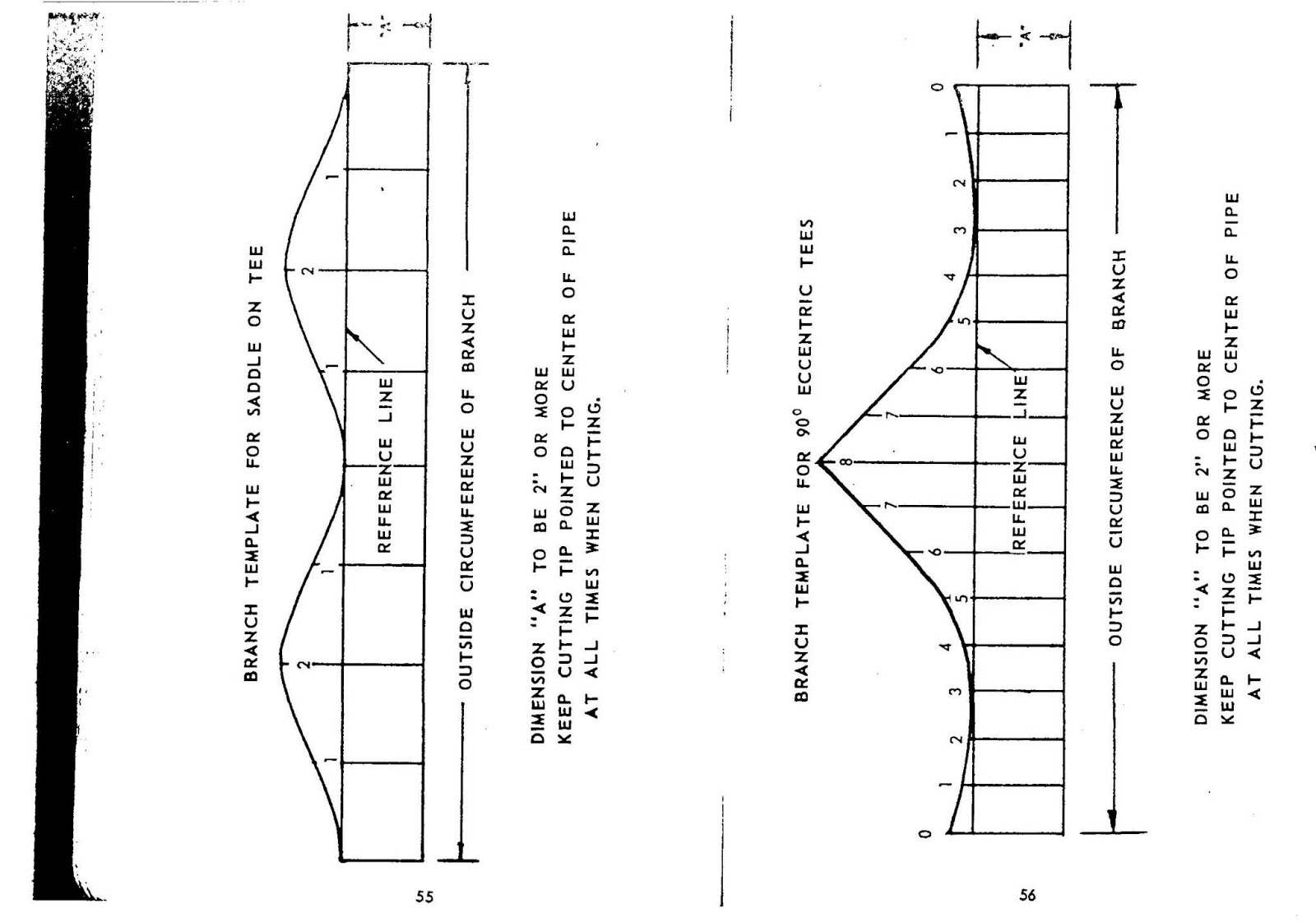

Simple easy to follow instructions on each template. Save time and money with less waste and a better fit. The resulting pattern will look like the profile of a saddle, a curved center section that goes over the second pipe and two curved sections that extend down on either side. Web making perfect pipe saddle cuts with a bandsaw or chopsaw: Place template, trace template, remove template, and start cutting.

True experts of a trade know those little simple tricks that make a job much easier. This is one of those tricks that makes working with pipe much easier. I learned this wonderful way of making saddle cuts years ago, but only recently learned v…. Web some folks use a paper or metal saddle template, which they then trace onto the pipe with soapstone, chalk, or marker. To join the pipes (in a saddle or fishmouth joint), we need to first trim them (coping) along that curve.

Place template, trace template, remove template, and start cutting. Simple easy to follow instructions on each template. Simple easy to follow instructions on each template. Web some folks use a paper or metal saddle template, which they then trace onto the pipe with soapstone, chalk, or marker. True experts of a trade know those little simple tricks that make a job much easier.

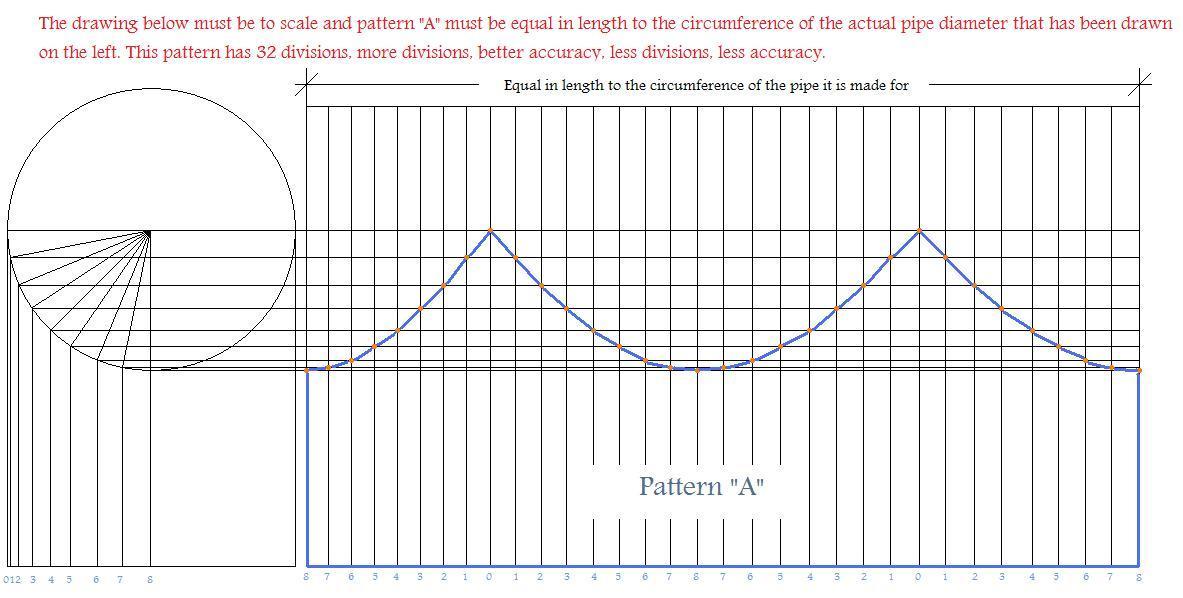

The resulting pattern will look like the profile of a saddle, a curved center section that goes over the second pipe and two curved sections that extend down on either side. Place template, trace template, remove template, and start cutting. To create the saddle, a welder then uses a handheld torch while slowly and steadily rotating the pipe to make the cut. To join the pipes (in a saddle or fishmouth joint), we need to first trim them (coping) along that curve. Web one step pipe template 12″ saddle.375w. Simple easy to follow instructions on each template. Web tube joint pattern generator. One step pipe template 12″ saddle.250w. The complete wrap around template with simple instructions imprinted on each template. Web this software lets you print pipe cutting templates to any printer or export to an autocad® dxf file. True experts of a trade know those little simple tricks that make a job much easier. I learned this wonderful way of making saddle cuts years ago, but only recently learned v…. Web a saddle cut is a way of cutting one pipe to match the outside curved surface of another pipe. Web making perfect pipe saddle cuts with a bandsaw or chopsaw: Save time and money with less waste and a better fit.

Simple Easy To Follow Instructions On Each Template.

Web making perfect pipe saddle cuts with a bandsaw or chopsaw: Choose the type of joint you want, enter the pipe sizes and desired dimensions, print a template on your printer, wrap the. Simple easy to follow instructions on each template. I learned this wonderful way of making saddle cuts years ago, but only recently learned v….

One Step Pipe Template 12″ Saddle.250W.

This is one of those tricks that makes working with pipe much easier. Web this software lets you print pipe cutting templates to any printer or export to an autocad® dxf file. Web some folks use a paper or metal saddle template, which they then trace onto the pipe with soapstone, chalk, or marker. Web creates 4 different cutting guides at 45, 90, 22.5, and saddle cut.

To Join The Pipes (In A Saddle Or Fishmouth Joint), We Need To First Trim Them (Coping) Along That Curve.

Web one step pipe template 12″ saddle.375w. True experts of a trade know those little simple tricks that make a job much easier. To create the saddle, a welder then uses a handheld torch while slowly and steadily rotating the pipe to make the cut. Place template, trace template, remove template, and start cutting.

The Complete Wrap Around Template With Simple Instructions Imprinted On Each Template.

The resulting pattern will look like the profile of a saddle, a curved center section that goes over the second pipe and two curved sections that extend down on either side. Web tube joint pattern generator. Save time and money with less waste and a better fit. Web a saddle cut is a way of cutting one pipe to match the outside curved surface of another pipe.