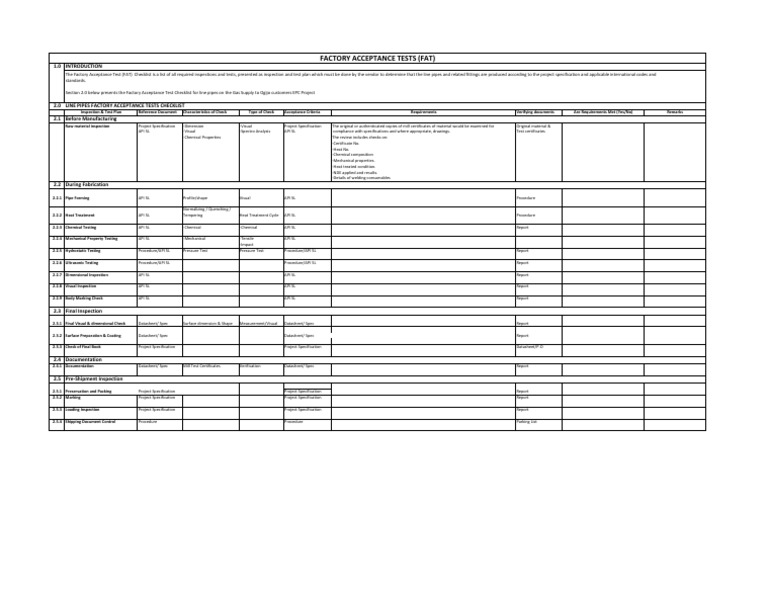

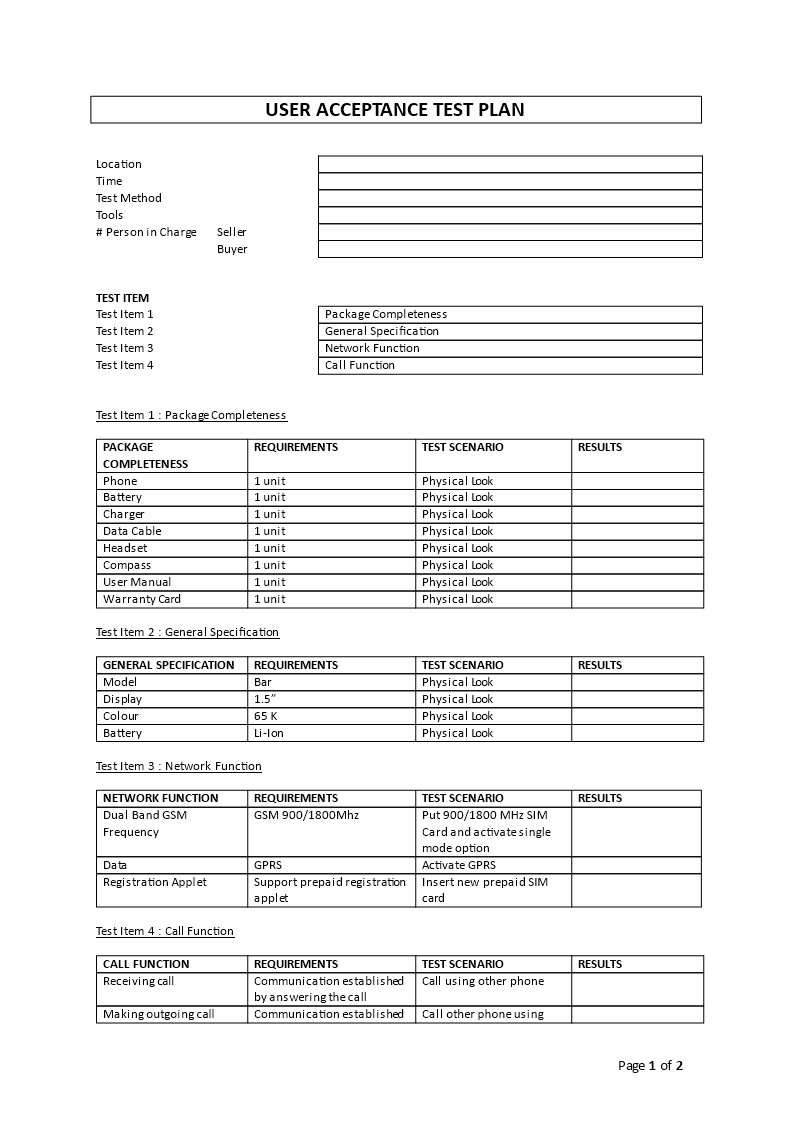

🟩 factory acceptance test report template; Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. Web factory acceptance tests (fats) are performed to verify that the equipment’s specification suits a buyer's requirements. Environmentequipmentproduct this test is done by sw. 🟩 factory acceptance test checklist;

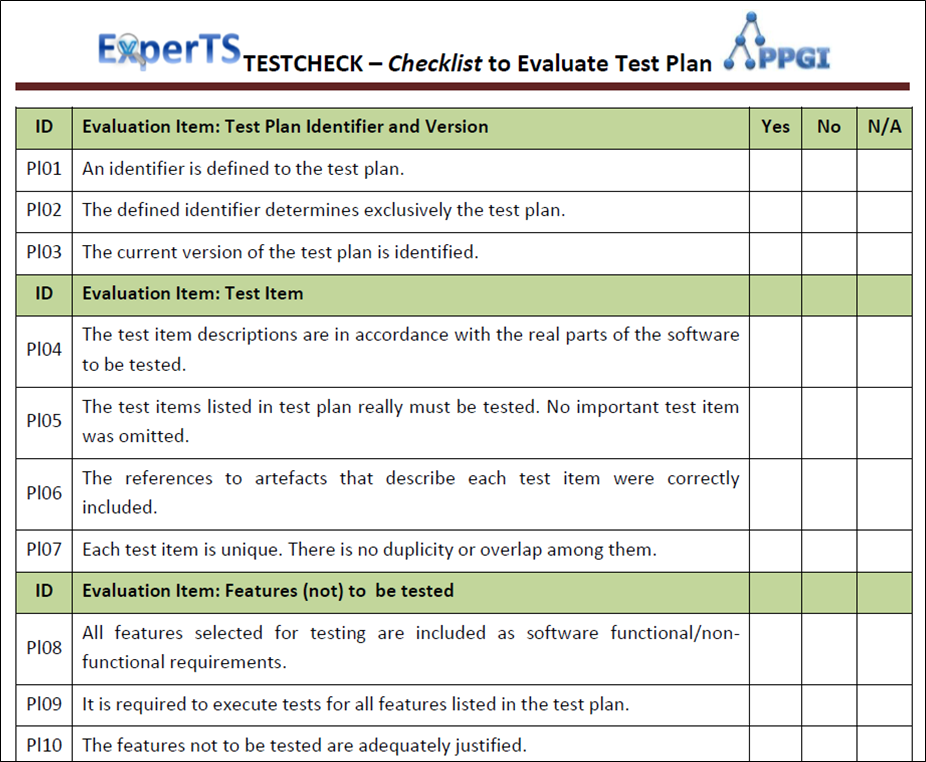

Sample protocol template is also available for download as pdf file. Web a description of the general approach. Web 🟩 how do you write a factory acceptance test method statement? Web facilitate a factory acceptance test for your company and your customers by using digital checklists for each factory acceptance protocol. Web pdf template, use this factory acceptance test (fat) checklist to document the complete::incomplete fat protocol, capture photo evidence of the entire fat procedure, including hazard identification, safety inspection and ergonomic assessment, specify the pass::fail acceptance criteria upon the actual fat, assign corrective actions for equipment.

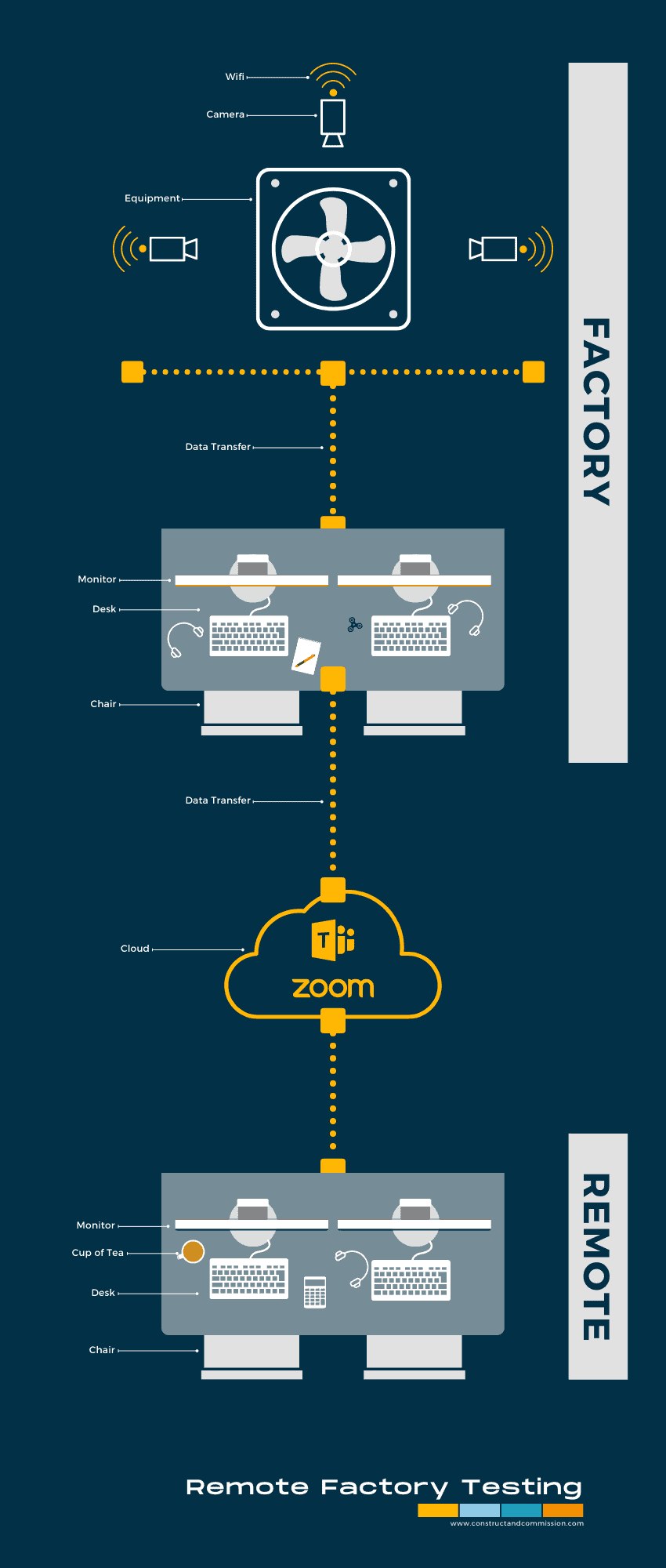

Environmentequipmentproduct this test is done by sw. 🟩 remote factory testing infographic; Express the user experience and expected outcomes criteria. It is also intended to register the outcomes of the activities and validate the functional requirements of the solar energy system (ses). Here are some key steps and tips for guidance:

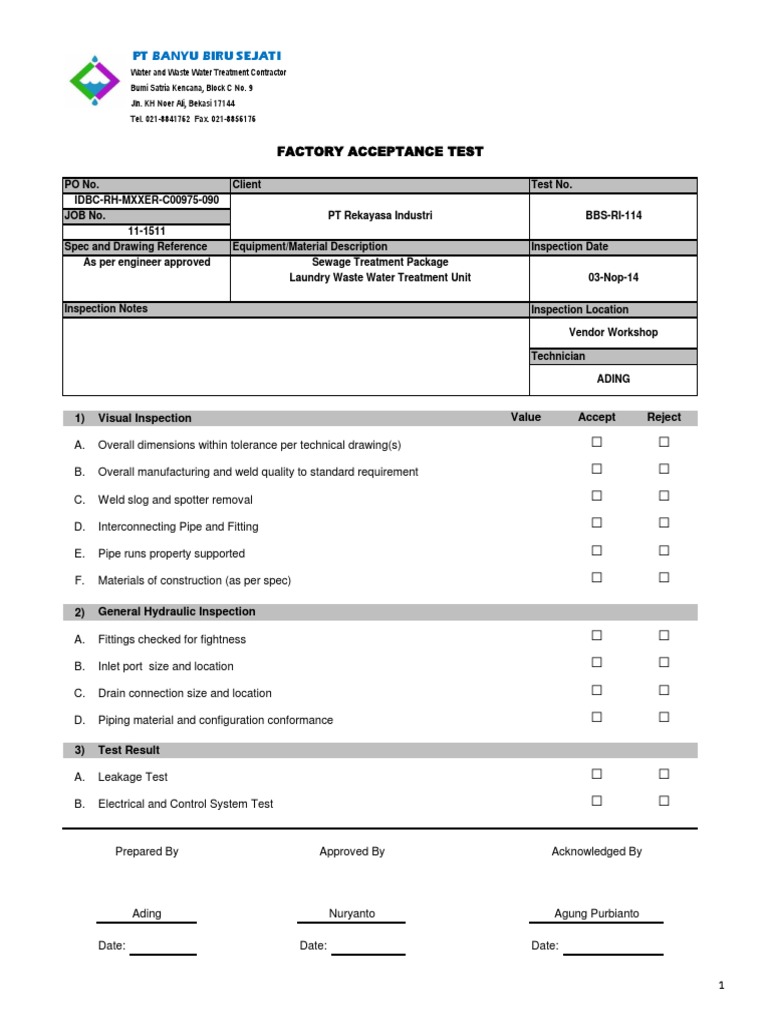

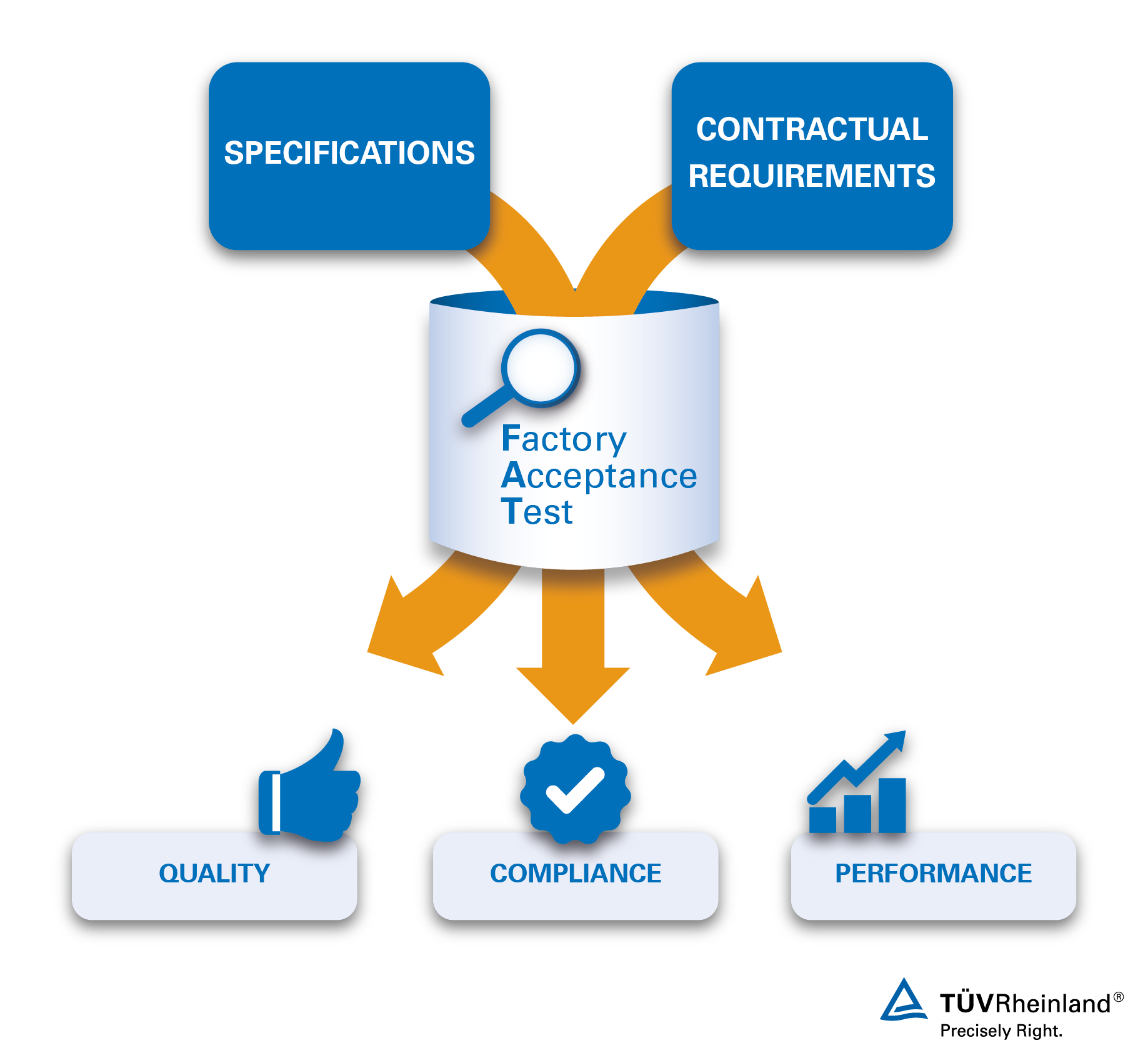

Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. This optional test is performed once the design and fabrication of the equipment are complete following approved test plans as agreed with the client. In case of power loss, the system must be protected in the following priority and the likelihood of damage must be minimized: Most sellers perform a dry test, which doesn’t need using a product. It is also intended to register the outcomes of the activities and validate the functional requirements of the solar energy system (ses). Web factory acceptance testing (fat) is a test performed for newly manufactured and packaged equipment by the vendor prior to shipping to ensure the equipment meets its intended purpose. Specification of the revision levels of the hardware and software to be specification of the exact configuration of equipment being tested. Safety at system failure & main switch check. Learn the steps and procedures of a fat and avoid the common mistakes by reading about how to. Web 🟩 how do you write a factory acceptance test method statement? Web this document provides a template for a factory acceptance test (fat) or site acceptance test (sat) for an unnamed system. Web in the world of industrial automation, a factory acceptance test or fat is simply a test for a newly manufactured control system that takes place at your factory or your workshop before you ship the control panel to the customer. Environmentequipmentproduct this test is done by sw. 🟩 factory acceptance test checklist; Web this factory acceptance template is a comprehensive validation test for outboard equipment (external effects unit), including ac power test, audio test, video test, control and performance test, and network test.

Web The Factory Acceptance Test (Fat) Checklist Assists You In Setting Clear Expectations For Machine Functionality.

Web a description of the general approach. Web factory acceptance tests (fats) are performed to verify that the equipment’s specification suits a buyer's requirements. ⬜ factory acceptance testing report template [ms word] ⬛ related articles; Web in the world of industrial automation, a factory acceptance test or fat is simply a test for a newly manufactured control system that takes place at your factory or your workshop before you ship the control panel to the customer.

Refer To The User Story Connected To The Acceptance Criteria.

Use it to validate that these expectations were met prior to shipment from the factory. This part focuses on a performance test for the equipment. 🟩 factory acceptance test report template; Express the user experience and expected outcomes criteria.

Web Facilitate A Factory Acceptance Test For Your Company And Your Customers By Using Digital Checklists For Each Factory Acceptance Protocol.

It ensures the equipment does not lack any critical requirements or issues that could make it useless in terms of any product, process, or regulatory requirements. Web the template applies mainly to system testing for hydropower plants, but can easily be modified for other plant types, since the system parts and functions designed by abb do not differ that much between the plant types. Web with operations1 you can digitally map your commissioning and increase productivity by +21%. A static review covers a detailed check of safety, mechanics, electronics, and accompanying documents.

Web This Document Provides A Template For A Factory Acceptance Test (Fat) Or Site Acceptance Test (Sat) For An Unnamed System.

🟩 factory acceptance test checklist; This optional test is performed once the design and fabrication of the equipment are complete following approved test plans as agreed with the client. Safety at system failure & main switch check. Instantly format your completed tests into timeline view or register view.